Automtic Control Casing Rotator casing equipment

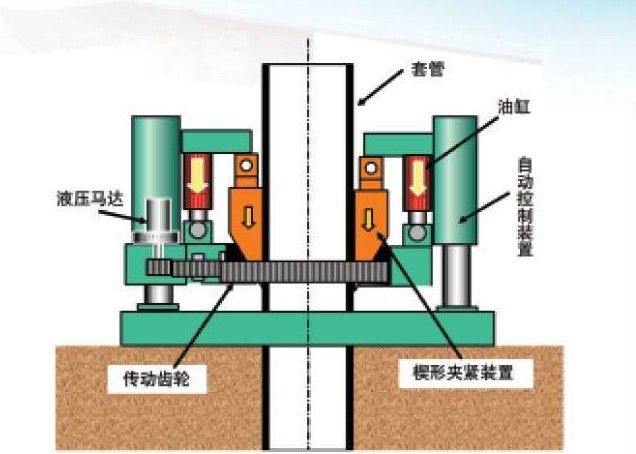

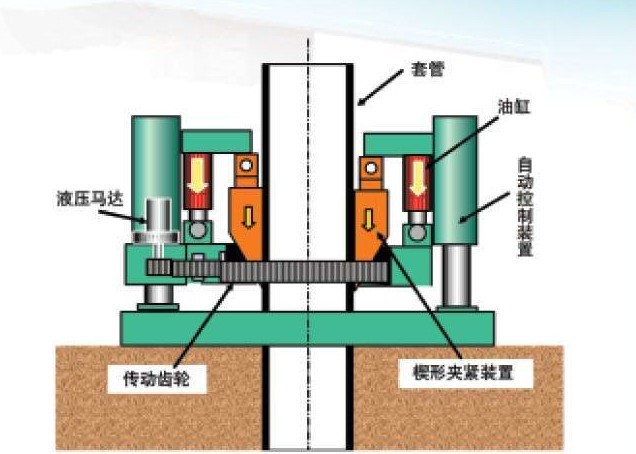

The components of casing rotator series

Working device Wedge clamping device

Being compared with the traditional clamping mechanism, it can clamp the casing no matter at what position, and keep the vertical accuracy of the casing; and the larger drawing resistance of casing causes greater lamp force.

Motor Reducer---4 sets of motor reducer can supply the sufficient torque, transfer a strong rotary force to the casing, which can adapt to the complicated stratum and cut obstructions.

Vertical device---Hydraulic vertical device ensures the verticality of drill holes, and corrects the casing angle timely in the construction.

Caliber change device---The convenient caliber change makes the equipment adapt to various requirements of caliber change.

Auxiliary clamping device---It can better ensure the verticality of casing, and additionally compensate for the problem of low crane capacity of the equipped crane during deep excavation.

Work traveling device---The crawler traveling device is with the function of hydraulic transverse expansion, which is convenient for the equipment to move automatically and conduct the pile core localization.

Hydraulic power station

Engine---The great power of engine can supply a huge torque for the equipment. It provides the machine with a great torque to work and make it adapt to any complicated and difficult stratum.

Convenient operating system---According to the working condition the operating system platform of micro computer can keep the

machine at an optimum working state by adjusting the speed, torque and pressing force, and promote

the work efficiency to the maximum.

Cutter head load automatic control system---When cutting the hard rock, it can well protect the cutter head and effectively enhance the cutting efficiency by the automatic control of computer.

Instant enhancement system---When encountering obstructions, it can instantly enhance the pulling force and torque to clear the obstruction.

Emergency system---The main function of control system is also set in the power station. When there is a malfunction, the emergency system can be adopted to complete the construction work.

Power station traveling device---The power station, which is convenient for traveling, can make the equipment travel freely on the construction site and complete the drill alignment; the support structure can ensure the stability and safety of equipment during working.

Casing

Crawler crane

Auxiliary machines--for remove the obstruction

Multi-head claw + Spiral drill head

The rotary drill head and spital drill head can be selected and matched for the multi-head claw according to the requirements.

It works at a state of low noise and low vibration.

It can choose the number of suspension wire rope, so the small-scaled crane can be adopted for cooperation.

Multi-head claw + rotary drilling bucket

The multihead claw is an internal excavation device of sleeve, which is powerful when removing the underground obstructions such as the reinforced concrete, stell pile and broken stone; it can effectively transfer the torque and pressing force of the sleeve.

Impact-grab bucket + heavy hammer

When the impact excavation cannot be conducted in the rock stratum or concrete piles, use the heavy hammer to repeat the impact, and excavate it with the impact-grab bucket after it is broken.

This is a commonly adopted construction method of the cooperation of impact-grab + heavy hammer.

Impact-grab bucket

The grab bucket is the main internal impact excavation device of the casing. It relies on the big and small hangers of crane to complete the impact and excavation work.

During operation, the impactgrab bucket falls freely along the internal wall of casing, with the fast falling speed and strong impact force, the hard stratum can be directly impacted and excavated with a high working efficiency.

The bucket blade is in the shape of circular arc with heavy bucket body, it can realize the underwater impact and excavation. With the built-in pulley block, the grabbing force is multiplied with the increasing lifting force.

| TR2005H |

| Diameter of drill hole |

mm |

Φ1000-Φ2000 |

|

| Rotary torque |

KN.m |

2965/1752/990 Instantaneous 3391 |

|

| Rotary speed |

rpm |

1.0/1.7/2.9 |

|

| Lower pressure of sleeve |

KN |

Max.600 |

|

| Pulling force of sleeve |

KN |

3760 Instantaneous 4300 |

|

| Pressure-pulling stroke |

mm |

600 |

|

| Weight |

ton |

46 |

|

| Engine model |

|

Cummins QSM11-335 |

|

| Engine Power |

Kw/rpm |

272/1800 |

|

| Fuel consumption of engine |

g/kwh |

216 |

|

| Weight |

ton |

8 |

|

| Control mode |

|

Wired remote control/ Wireless remote control |

|

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!