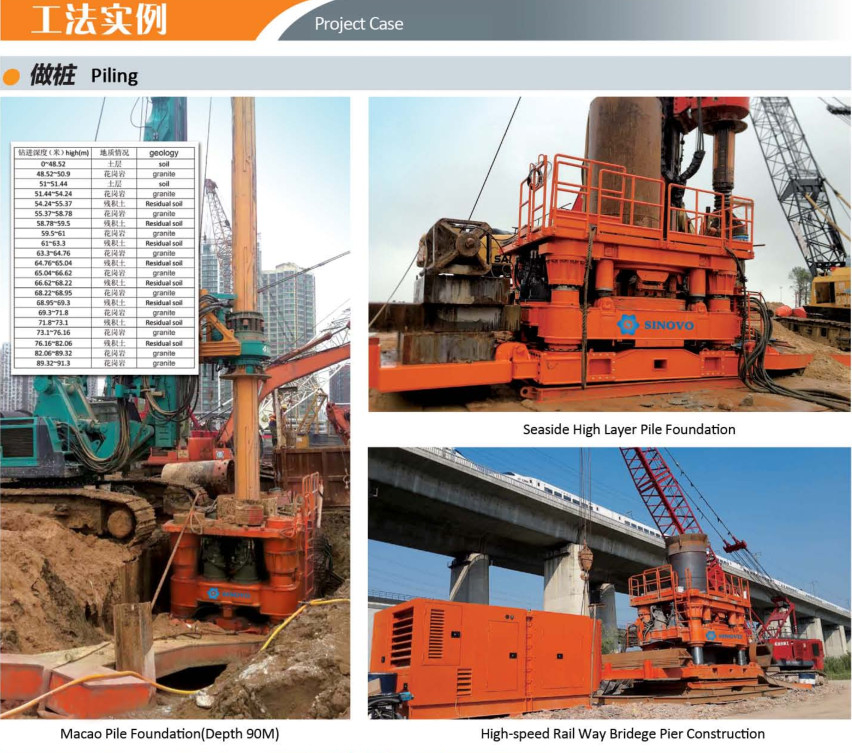

TR2005H casing rotator,it is a new, environmentally-friendly and highly efficient drilling technology. In recent years, it is widely adopted in the projects such as the constructions of urban subway, articulation pile of deep foundation pit enclosure, clearance of waste piles ( underground obstructions ), high-speed rail, road and bridge, and urban construction piles, as well as the reinforcement of reservoir dam.

1. Foundation pile, continuous wall:

A. Foundation piles for high-speed rail, road and bridge and house building.

B. Articulation pile constructions which are required to be excavated, such as subway platforms, underground architectures, continuous walls

C. Water retaining wall of reservoir reinforcement.

2. Drilling gravels, boulders and karst caves

A. It is allowable to conduct the foundation pile construction at mountain lands with gravel and boulder formations.

B. It is allowable to conduct operation and cast the foundation piles at he thick quicksand formation and necking down stratum or the filling layer.

C. Conduct rock-socketed drilling to the rock stratum, cast the foundation pile.

3. Cut the rock stratum

A.Conduct the rock-socketed drilling to the cast-in-place piles.

B.Drill through-holes on the rock bed (shafts and ventilation holes)

4. Clear the underground obstructions

A.During the urban construction and bridge rebuilding, the obstructions such as the steel reinforced concrete pile, steel pipe pile, H steel pile, pc pile and wood pile can be cleared directly, and cast the foundation pile on the spot.

5. Deep excavation

A. Conduct the in-place casting or steel pipe pile inserting for the deep foundation improvement.

B. Excavate deep wells for construction use in the constructions of reservoir and tunnel.

The advantages of adopting the casing rotator for construction

1. The drilling speed is fast and reaches about 14m/h for the general soil layer;

2. The drilling depth is large and reaches about 80m according to the situation of soil layer;

3. No noise, no vibration, and high safety;

4. The hole forming verticality is easy to master, which can be accurate to 1/500;

5. The hole clearing is thorough and fast. The drilling mud at the hole bottom can be clear to about 3.0cm;

6. Without mud, clean working surface, good environmental friendliness, avoiding the possibility for mud to enter the concrete, high pile quality, enhancing the bond stress of concrete to the steel bar;

7. During construction drilling, the characteristics of stratum and rock can be directly distinguished;

8. No hole collapse will be caused, and the hole forming quality is high;

9. The hole forming diameter is standard, with little filling factor. Being compared with other hole forming methods, it can save a lot of concrete usage;

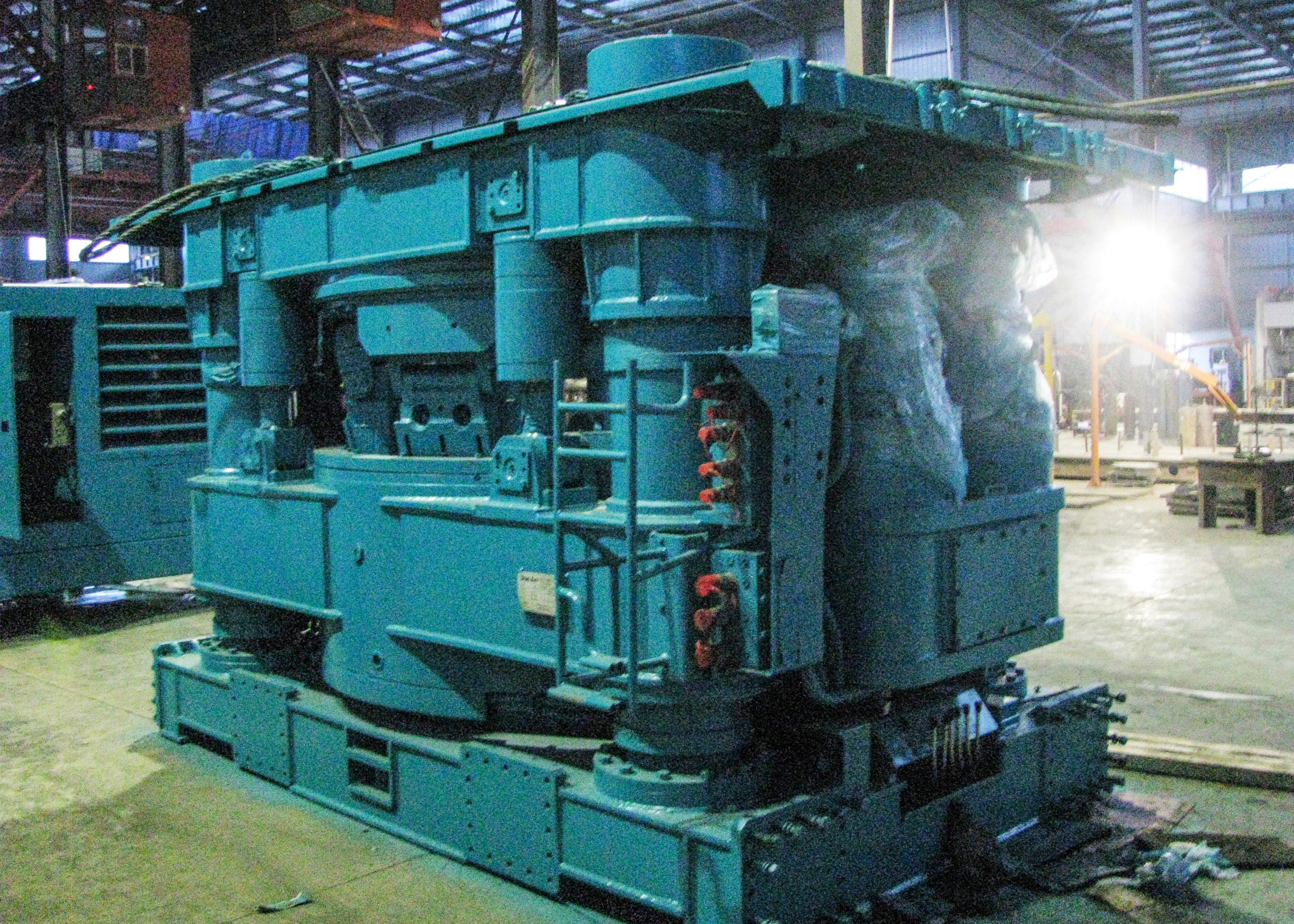

Technical parameters

| TR2005H |

| Working device |

Diameter of drill hole |

mm |

Φ1000-Φ2000 |

| |

Rotary torque |

KN.m |

2965/1752/990 Instantaneous 3391 |

| |

Rotary speed |

rpm |

1.0/1.7/2.9 |

| |

Lower pressure of sleeve |

KN |

Max.600KN+Dead weight260KN |

| |

Pulling force of sleeve |

KN |

3760 Instantaneous 4300 |

| |

Pressure-pulling stroke |

mm |

750 |

| |

Weight |

ton |

45+(selection and installation of track)9 |

| Hydraulic power station |

Engine model |

|

Cummins QSM11-335 |

| |

Engine Power |

Kw/rpm |

272/1800 |

| |

Full consumption of engine |

g/kwh |

216(when the maximum power rate) |

| |

Weight |

ton |

8+(Walking wheels are optional) 0.3 |

| |

Control mode |

|

Wired remote control |

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!